- HEAVY DUTY 4 POST CAR PARKING LIFT (TUBE COLUMN TYPE)

- 4 POST TRIPLE STACKER LIFT

- DOUBLE WIDE 4 POST CAR PARKING LIFT

- TILTING CAR PARKING LIFT

- SINGLE POST CAR PARKING LIFT

- TWO POST CAR PARKING LIFT

- FOUR POST CAR PARKING LIFT

(TWO PARKING SPACE) - SCISSOR PARKING LIFT

- STACKER PARKING LIFT

- PUZZLE PARKING SYSTEM

- PUZZLE PARKING SYSTEM (BACK CANTILEVER)

- ROTARY PARKING SYSTEM

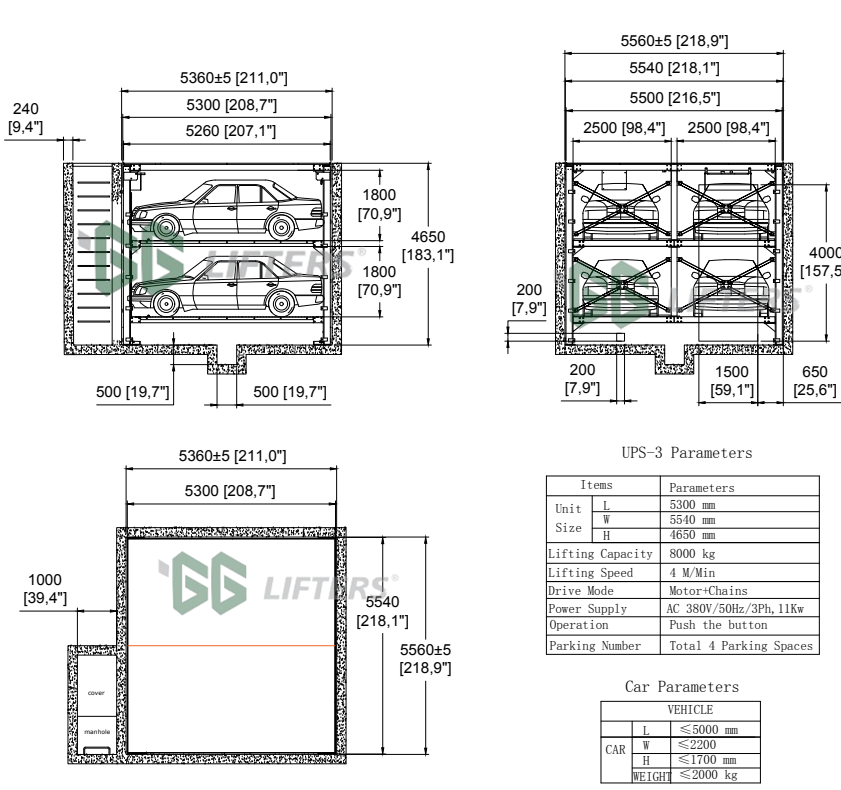

DOUBLE WIDTH 4 POST UNDERGROUND CAR PARKING SYSTEM(DOUBLE WIDTH)

1. For independent parking, Directly park or pick up the car at any level independently.

2. Double wide platforms make it avaiable for 4 cars hidden underground, 2 cars at each level, space saving. Top platform is used as roof & drive through. Hide cars underground, no visible impact! People or cars could go thought on the top platform.

3. Offer the most net width within narrow external width. Net entrance width could be 5400mm in pit with width of 5850mm!

4. Top platform is made of diamond plate and lower platform is galvanized wave plates.

5. Hydraulic driven through 4 ea hydraulic cylinders system and chain balance system.

6. Control valve group (package) to divide oil equally to the 4 cylinders and control the hydraulic system.

7. Simple steel structure, easy for installation and maintenance.

8. Electric operation box is equipped with “Dead Man” Push Buttons (UP/Down) & Emergency and ON/ OFF “Key Switch “where the user can’t take it out unless the lift is fully down inside the pit.

9. Electric Operation Box is operated by 24 V to protect against short circuit.

10. 1 ea limit switch in every level to stop platforms at predefined heights.

11. Electric sensors to confirm no persons or objects before rising up/down the platforms.

12. Front and back wave plates are removable for easy access to the pit ground floor in case of emergency.

13. Tire stoppers in each platform to ensure correct placement of the car.

14. Hydraulic power unit is fixed on the front together with facility steel structure under upper platform.

15. Flexible design according to customer requirements, suitable for residential & commercial use.

16. Units are designed and built according to EN1493: 2010 and EN14010: 2003 standards.

| Model | UPS-2D |

| Platform number | 3 platforms, and among which top platform of drive through type just used as roof and drive through ONLY. |

| max load each platform | 2000kg * 2 (8800 lbs), each car max 2000kg (4400 lbs) |

| load per wheel max | 500kg (1100 lbs) |

| Car number (drive through type) | 4 cars underground. Top platform of drive through type just used as roof and drive through ONLY. |

| Internal pit dimensions (mm) | 5850 * 5300 * 4650 mm ( 230.31" * 209" * 183.07") |

| Space requirement when lifting up (mm) | 5850 * 5300 * 4000 mm ( 230.31" * 209" * 157.5") |

| net parking space each level (mm) | 5400 * 5240 * 1800 mm (212.72" * 206.37" * 70.86") |

| Max vehicle size (mm) | 5000 * 2300 * 1700 mm (209" * 90.55" * 66.93") |

| Electric parts | Original Chint |

| Lock release type | Electromagnetic lock release |

| platform type | Top platform is diamond plate, and lower platforms is galvanized wave plates |

| Safety Devices | 4 ea anti-falling locks, anti-explosion valve |

| Operation Type | Push buttons on operation box with "UP", "DOWN", "EMERGENCY STOP" buttons |

| Motor Capacity | 11 kw (14.75 hp) |

Drawing

ENQUIRY MESSAGE

- Prev:No more!

- Next:4 POST UNDERGROUND CAR PARKING SYSTEM